LAMINATED NECKS

We make our necks using long established methods of instrument building and best practice, paying particular care to the lay of grain and structure in order to produce necks that have inherent strength and stability.

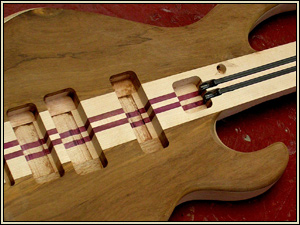

The main battens and alternate laminations are all cut from the same piece of timber, with the contrast laminations being incorporated into the neck log not only to enhance strength but, just as importantly, to influence the tonal characteristics of the instrument.

This is why we make Maple our material of choice for neck construction. It has a density of approximately 600Kg per cubic metre and has a close, straight hard grain that produces a clear tone, perfect for electric bass guitars (and guitars for that matter). For Custom builds we are very happy to use your own timber preference and will work with you to achieve the sound you want.

For the accent laminations we mainly use Purpleheart which is a member of the Peltogyne family of timbers and with a density around 8oo Kg per cubic metre is ideal for contrast laminations. It looks fabulous with its vibrant colouring and distinctive grain. Best used in small quantities, it adds depth to the tone and helps expand the harmonic response of the instrument. As an alternative, sometimes we will use Walnut or Imbuya for the neck laminations on fretless models which can ‘open up’ the tone a little.

The Caldera is fitted with twin truss-rods. These are of a ‘double acting’ pattern which allow for compensation of fore or back bow and to some degree a bit of offset thereby allowing for pretty much every set-up preference. Adjustable at the body end of the fingerboard by removing the matching cover the truss-rods can be tweaked independently further enhancing adjustment options. The design and installation is executed in such a way that unwanted vibration and buzzing is virtually impossible.

Five and six string models have a unique neck construction featuring a tapering centre lamination and trapezoidal truss-rod fitment which not only looks fantastic but has significant implications for neck integrity. Tapering the centre lamination helps maintain the mass of the two main battens flanking the length of the neck whilst at the same time triangulates the whole neck construction, further improving strength. Having the truss-rods offset to one another also theoretically makes possible helical adjustment which may be particularly useful in wider necked multi stringed bass guitars. We also carve asymmetrically to make the bass as comfortable as possible and improve playability.

Every Caldera is built on the neck-through principle and they always have been, even with my first adventures in guitar building circa 1970 before I’d ever heard of the other established makers who use this method, just seemed like the logical way to do it!

Have you read about our custom noiseless pickups and bridges?