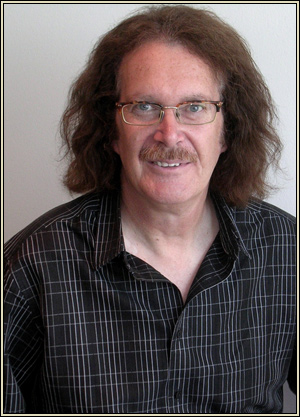

JOSH HAMILTON

MASTER LUTHIER

Josh has been making high quality musical instruments since (but not including) his first ‘guitar’ at the age of 12.

In his own words:

“I met a school friend whom I hadn’t seen for a while and he invited me back to his place. In the middle of the play room stood a Marshall amplifier on top of a pair of 4×12’s with a guitar leaning against them. ‘This is what I’m doing now’ Brian said as he picked up the guitar and bashed out some twelve bar blues. And that was it, the pivotal moment! No more model aeroplanes and radio control boats, I was hooked.

Me being me, instead of pestering the folks for my own Marshall stack and Strat, I set about doing it myself. My cricket bat was immediately sawn, planed drilled and sanded to make a neck. Dad’s collection of wood had the body sorted with some pieces of batten-board to which the neck was fixed. As far as bridge, nut, tailpiece and scratch-plate were concerned these were made from various bits of scrap. Machine heads were simply woodscrews but the most bizarre items of all were the strings, made by unwinding bicycle brake cables. As musical as a crow, gave a whole new meaning to the term shredding (finger tips, that is) and impossible to tune. Oh yes I forgot to say it had no pickups!

Well, that was Mk 1, quickly confined to the trash-can.

For my next venture into the world of electric guitars, I did some research, and borrowed Brian’s Strat’ copy. Sorry mate but I took it completely to bits, measuring everything and trying to work out why all the various bits were the way they were. Other than taking the covers off the pickups I did no more than measure the DC resistance (they were all around 3.5k) and attempted to establish the gauge of the wire using my dad’s micrometer.

Dad took me to a timber merchant and I came away with some mahogany and ash. I had seen a great looking guitar in a photograph which I later found out was an Gibson SG and decided I would make one that looked like that, so I scaled the picture and set to with chisels and spokeshaves. I saved up my pocket money and bought proper hardware and a pair of pickups.

The result was not as bad as you might think. It was a bit heavy, neck was too chunky (no truss-rod) and the brushed polyurethane finish was OK from a distance.

But it was a playable electric guitar and some of my friends were pretty impressed with it, if not with my playing.

When I was thirteen at school we had a newly qualified woodwork teacher helping out who also played guitar, which he often did in class instead of teaching us how to make coffee tables, bird boxes and other such interesting items(!) I couldn’t believe my luck and asked him endlessly about making and playing the guitar. I asked him if he would help me make another example of my earlier attempt. This was a new beginning for me. I learned so much and it all started making sense. All the mysteries, like truss-rods, pick-ups etcetera were being wiped away and Mk 3, another in the SG style took shape. With my teachers guidance I made this one ‘properly’ with a jointed set neck, truss-rod and correctly aligned neck. The guitar was mahogany again but this time I had rosewood for the fingerboard and quality nickel silver fret wire. Using some hardware store pot magnets and wire supplied by one of my physics teachers, I set about making a pair of pickups. I wound them by hand, no winding machine then! Each pickup took almost a week of spare time to hand wind around 6000 turns of impossibly fine wire, but I did it and no breaks. They were single coils but with the type of magnet used they were effectively twin pole and produced a pretty good tone with a decent amount of power. They came out around 4.5k and both had been wound to the same spec. I was delighted with the whole project and later sold the guitar for around £35 (quite a lot at the time) to a friend in the sixth form who actually gigged it.

As well as my growing obsession for electric guitars I also had for a fascination for electronics and had made several uninformed experiments with my sisters ‘Dansette’ record player with a view to using it as an amplifier. The main problem was of course balancing the input as it was made for use with a ceramic cartridge and I was wanting to use it with low output magnetic pickups. Also, there was a considerable amount of hum, which I later realised was caused by an earth loop. In an attempt to remedy the hum I had read in a book about amplification that the internal ground should be connected to the negative rail of the power supply (not in this case though!). I discovered later, after the electricity company had come along to re-establish the power supply to our house and six of our neighbours that connecting the resultant ground to the domestic water supply as a means of earthing the device was not necessarily a good idea.

I told my physics teacher about the incident and he suggested a bit of additional tuition in the application of electricity and the science of electronics. He showed me the basics of amplifier design and my first ‘proper’ amplifier was a home-made 60 watt unit with volume, bass, middle, treble and presence and a whopping great 18″ bass speaker. It was all tube and hand wired using discrete components mounted on tag strips. This was how it was done back then but is now considered ‘boutique’. I used the amp for a few years until I started gigging bigger venues when I switched to commercial equipment.

I had, in the meantime in an attempt to boost the output of my ‘pot’ magnet pickup equipped guitar, designed, again with the help of my physics teacher, a small pre-amp with some tone shaping capability which I fitted into the guitar. At the same time I had also discovered Jack Bruce and was absolutely blown away by his amazing style, presence and musicianship. He also played a bass that looked remarkably like the two guitars I had made based on the SG. This was pivotal moment number two.

I was saddened to read of the passing of Jack, he was an enormous influence on me and the inspiration for my attempts at playing the bass. He will be much missed by me and I’m sure countless other people around the world. My condolences to his family.

Armed with all the knowledge gained from my previous builds and the guidance of the extraordinarily supportive teachers I now set about building my first ‘proper’ bass guitar. Inevitably it was going to be an EB3 derivative and was built to the same scale length and basic overall design; however, there were some fundamental differences. The fingerboard was figured maple on a mahogany neck which was set into a solid maple body. I had progressed with my pickups to a humbucking design, but instead of Gibson’s sidewinder design for the neck I decided to try two coils on one row of simple bar magnets. For the bridge pickup a more conventional humbucking type with two rows of magnets and twin coils. I had no selector switch for the pickups, just a pair of volumes with my on-board pre-amp for tone shaping and gain. This bass sounded fantastic and finished in gloss black nitro-cellulose it looked good too. I switched to playing the bass and used that particular one for almost ten years, until family commitments curtailed the gigging for a while. When I say I played it what I really mean is I occasionally got to play it, that was when my bass playing (and some guitarist) friends gave me it back. Everybody loved it and it was always in demand. I’m sure if I’d had the time I could have sold as many as I could have made.

On leaving school and after an inappropriate three months as a stock control clerk at an engineering works I went to work at The Early Music Workshops in my home town. This was a pet project of a Director of one of the countries’ largest retailers of all things to do with music, from grand pianos, violins, sheet music etc, etc. Richard Wood had established the workshop to satisfy an increasing demand for renaissance and baroque period musical instruments.

I joined the workshop not quite at the beginning, but pretty much at the start of things and couldn’t believe my good fortune to be working in this kind of environment. Everybody in the workshop was a musician. Jonathan, the boss played the cello and his brother-in-law JB played piano and assorted keyboards. Peter, a semi-pro bass player who went on to session work in Miami and Rick who was a wonderful folk writer and guitar player, a huge Hendrix fan at the time. Shortly after I started, Steve, who played rhythm guitar arrived, and then Simon who was amazing on electric guitar.

Surrounded by like-minded people and making musical instruments, this was a perfect opportunity to develop my skills and ideas and practice all the techniques I had started to learn at school.

I learned a huge amount about not just instrument making and all the different types of tonewoods, but also engineering, tool and machine tool design and construction. Because of the nature of the instruments we were making we had to make a lot of the tooling and equipment ourselves and amongst other things we made our own copy router, sanding thicknesser, arch-top copier for reproducing carved tops for viols and similar arch top instruments and a whole host of smaller devices, jigs and cutters.

I was with the EMWS for eleven years and while I was there for the most part playing bass in three different bands and being influenced by very diverse styles. One band in particular really showed me the importance of having quality equipment. We were playing just about everything from heavy rock, blues, funk and disco. During this time I used two of my own basses. We practised four nights a week after work for three to four hours and gigged the other three nights which really tested not only our stamina but also the reliability of our gear. I had made for myself another short scale in the EB3 style but this time all maple and with higher output pickups but no EQ. This was the one I used for practise sessions and playing with friends for fun. The other was a 35″ scale neck-through with a laminated wenge neck and mahogany and maple body. There were three pickups, all single coils and the EQ which had now evolved into a mid and bass boost. It had a lovely tone, clean and powerful and was kept for the more special gigs and for showing-off. It was too heavy, mainly because of the large body and those twin quarter inch steel truss rods. This one disappeared after a couple of years. We were always borrowing each other’s equipment and I suspect a friend of a friend may have taken a shine to it. The short scale was the real workhorse though and went through a metamorphosis of changing pickups, bridges, electronics and various gauges of fret wire. Between these two very different basses I had developed the many ideas which have been further refined to evolve into the models I now produce.

Essentially our new models are based on the long scale but with a more contemporary style. A smaller, lighter body and modern neck profiles make them very comfortable to play. Electronically they are absolutely superb with amazingly expressive pickups and EQ that further expands the potential of the instrument.

During my time at the EMWS I made contacts with musicians from all around the world and after leaving there to manage the workshops at the National Media Museum in Bradford (known then as the National Museum of Photography Film and Television) I continued making to commission many of the stringed early instruments for which I had the greatest affinity. In and amongst I made a number of basses and guitars until 1992 when other commitments and complications meant I had to concentrate my efforts in other directions.

Moving swiftly along to 2005, the opportunity to get back to what is most important to me creatively came about. Looking back at my previous instruments and taking note of the current trends in modern bass design I began to prototype a bass which would tick as many boxes as possible. Combining traditional materials with more modern designs and revised components by 2007 we had a small range of four and five string basses covering fretted, fretless, active and passive options and all with the flexibility to be tailored to individual preferences.