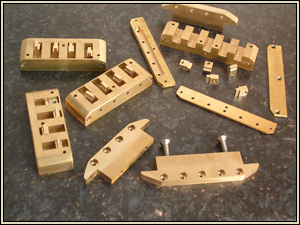

HAND CRAFTED BRIDGES

Our bridge design is a culmination of many years experience both as a player and a maker.

Having played most popular makes of instrument over the years and also with building my own there have been some aspects of all which have been good, some bad and a few absolutely downright unbelievably horrible.

My own thoughts on the subject of bridge design are manifold and I shall explain how the bridges we now use came about.

The first question I asked was, ‘what is the principle function?’

The answer: To provide positive location for the strings in relation to the fingerboard and the nut.

Each individual saddle is machined to fit into its channel and therefore fits very closely, eliminating sideways movement without the need for screws.

The entire downward pressure of the string bearing upon the saddle is taken on the block which ensures maximum stability and tonal transmission.

Secondly I considered the adjustment requirements and what form these should take.

An essential function is independent adjustment for the intonation of each string and so each saddle is hand cut to the gauge of string used and is closely fitted into its own channel in the bridge block. Intonation is facilitated by rotation of the machine screw on which the saddle is located. The screws are made to aerospace tolerances and the threads cut into the saddles are hand cut to very fine tolerances virtually eliminating backlash and unwanted movement.

The intonation screws are held captive by the cap at the back of the bridge which has a precision milled cavity designed to contain the screw heads but without allowing any fore or back movement. Every slight movement imparted to the screw is translated to the saddle and it will hold its position perfectly.

OK, that’s intonation and registration taken care of, what about height? Simple really. To ensure maximum tonal transmission the bridge cavity routed into the top of the body has a heavy gauge brass plate bonded into the bottom. The bridge has four dog-point grub-screws in the main block which, as with the intonation screws are an interference fit in the block and can be adjusted to raise or lower the bridge as desired.

As the saddles are hand cut to provide the correct string height no provision is made for individual adjustment as this is not necessary and therefore removes the need for even more screws to scrape your knuckles on and compromise the tone.

We offer both equal (standard) and graduated (custom option) pitch bridges. The saddles of our graduated bridges are spaced to compensate for the differing gauges of the strings, therefore maintaining an equal distance between the strings themselves and not just their centres.

All our bridges (since 2014) are fitted with ‘Lock-Down’ screws. These are a recent refinement designed to enhance tonal transmission from the strings and into the body. The are accessed from the rear of the body below the bridge and simply lock the bridge block against it’s cavity plate rather than simply relying on string pressure. One screw is fitted for four string models and two are provided for five or more string basses.

The last but certainly not the least important points for consideration are aesthetics and comfort.

With a low profile and smooth shape the whole bridge assembly fits neatly into the top of the bass complementing the elegance and integrity of the bass’ design and with a minimum of moving parts, clean lines and functionality the bridge fulfils all our design criteria perfectly.

As with the string anchor the bridge, which is made of the same material, can be finished in a variety of ways. Bright chrome or Nickel, Gold, Rhodium or just plain natural brass are just some of the options available.

Have you read about our laminated necks and pickups?